Role of Transport and Plastic Belts in Industrial Applications

Transportriemen or transport belts, often referred to as conveyor belts, are continuous loops of material designed to move goods from one point to another within a facility or between different locations. Their versatility and adaptability have made them an essential part of various industries, including manufacturing, mining, food processing, airports, and distribution centers.

1. Manufacturing: In manufacturing plants, transport belts play a key role in the production process. They move raw materials, components, and finished products between different stages of production, ensuring a seamless flow and reducing manual handling.

2. Logistics and Distribution: In warehouses and distribution centers, transport belts efficiently move packages and goods, optimizing the order fulfillment process and reducing the time required to handle and transport items.

3. Mining and Construction: In the mining and construction industries, heavy-duty transport belts are used to transport materials such as ores, aggregates, and construction materials over long distances, enabling the efficient extraction and processing of resources.

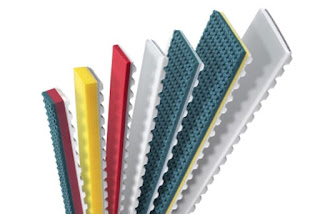

Kunststoff Riemen or plastic belts, as a specific type of transport belt, offer distinct advantages over other materials like rubber or fabric. These belts are made from various types of plastics, such as polyethylene, polypropylene, or polyurethane, depending on the application requirements.

1. Durability and Strength: Plastic belts are known for their excellent durability and strength, making them suitable for handling heavy loads and enduring challenging industrial environments.

2. Chemical Resistance: Many plastic belts have inherent chemical resistance properties, which make them ideal for applications where exposure to chemicals or harsh substances is a concern.

3. Hygiene and Cleanability: Plastic belts are often used in industries with strict hygiene requirements, like food processing, as they are easy to clean and maintain.

Comments

Post a Comment